Detailed explanation and application of the process of pressure rivet nuts and pull rivet nuts

Data:

2025-06-18 23:14

Detailed explanation and application of the process of pressure rivet nuts and pull rivet nuts

Compression rivet nuts are also called nut caps, pull caps, and instant pull caps. They are used in the fastening field of various metal sheet, pipe and other manufacturing industries.

Compression rivet nuts are developed to address the shortcomings of metal sheet and thin tube welding nuts that are easy to dissolve and internal thread slippage. It does not require internal threads or welding nuts, and the riveting is firm, efficient, and easy to use.

Before construction, please confirm the model and specifications of the compression rivet nut according to the drawing requirements to ensure that the correct compression rivet nut is used to prevent the use of wrong specifications and models.

Operating specifications for pressure rivet nuts

Confirm the specifications of the rivet nuts

Before construction, first confirm the model and specifications of the rivet nuts according to the drawing requirements to ensure that the correct rivet nuts are used to prevent the use of wrong specifications and models.

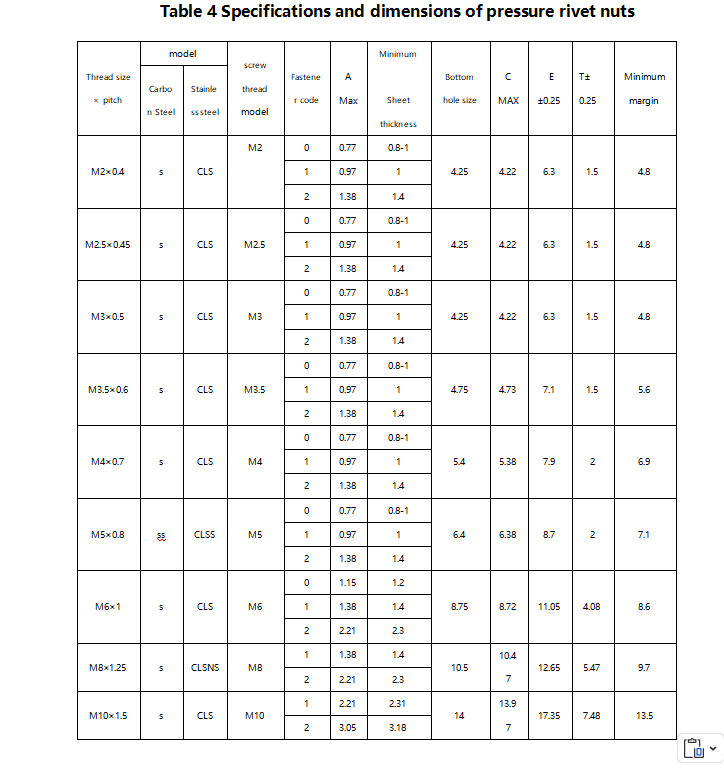

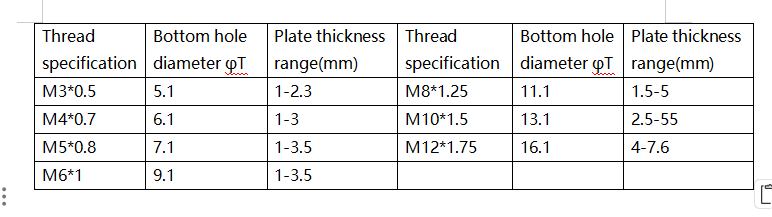

Bottom hole size confirmation

Before officially pulling the rivet nut, it is necessary to confirm whether the bottom hole size of the plate meets the bottom hole size requirements of each model. If it does not meet the requirements, stop the riveting operation. The specific bottom hole size is shown in Table 4

Adjusting the equipment

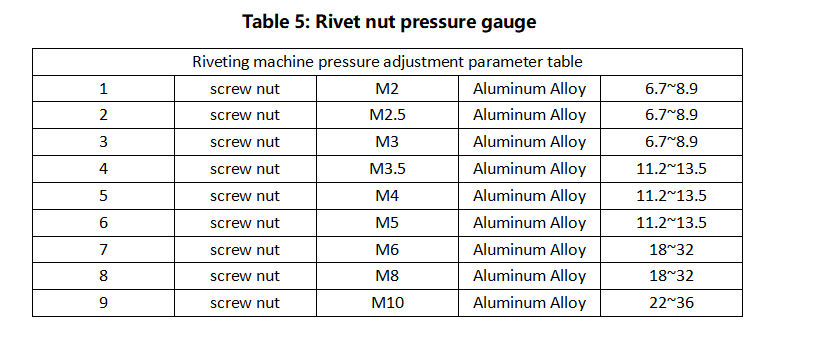

After the materials are prepared, select the corresponding rivet head according to the specifications of the nut to be riveted. Replace the rivet head and adjust the pressure to ensure that the pressure is within the specified pressure range. The specific pressure is shown in Table 5.

Install the rivet nuts

After the equipment is adjusted, start riveting the nut. Place the rivet nut into the hole of the plate, adjust the position of the nut and the upper hole of the upper die, ensure that the lower hole is in a horizontal position, and then apply pressure to the rivet nut to press the nut into the plate.

Inspection

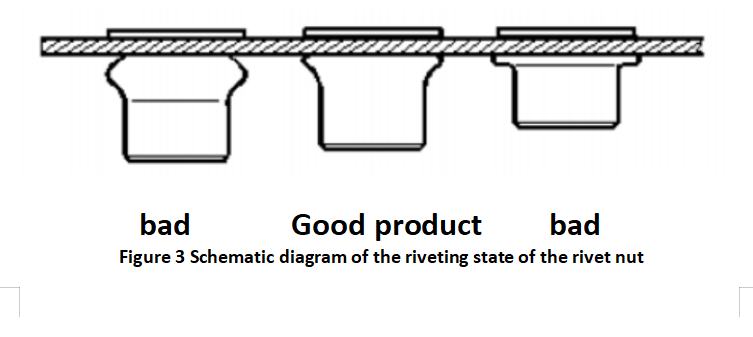

Appearance inspection

After riveting, there shall be no protrusions or depressions around the rivet nut, no obvious deformation, and no obvious embossing or mold marks that cannot be concealed by surface treatment.

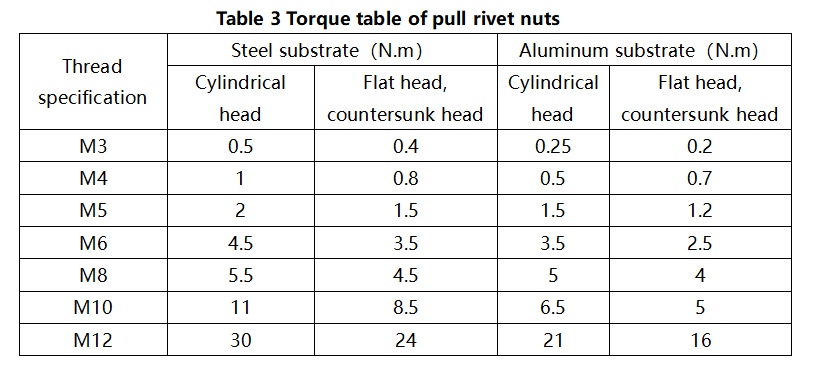

Torque detection

After riveting, the riveted parts must not be tilted, loose, or fall off, and their firmness must be tested: the torque value tested with a torque wrench tester must comply with the specified value, see Table 6.

Table 6 Rivet nut torque table

Rivet nut model description

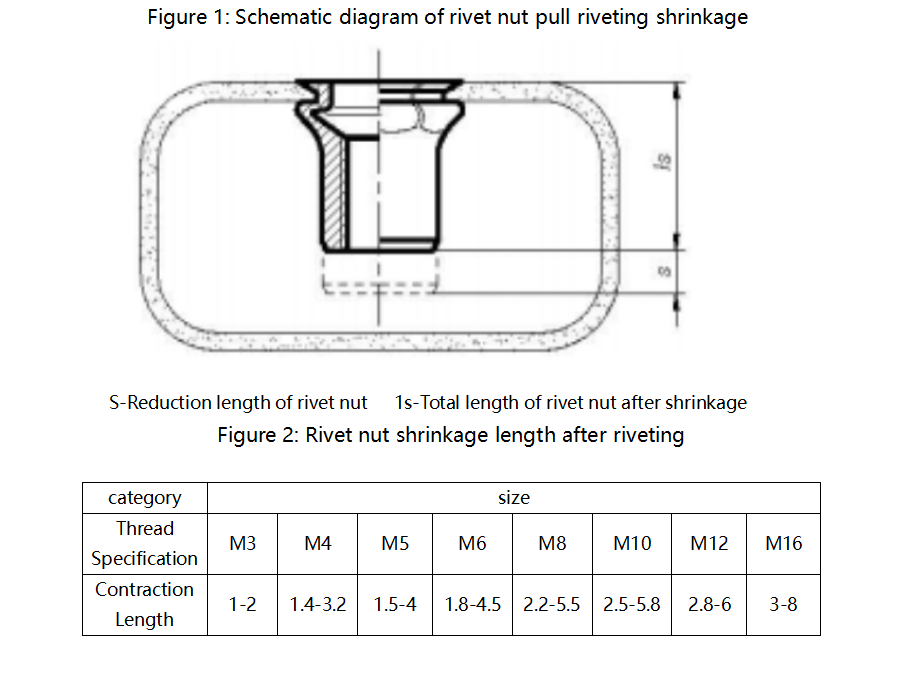

Check and test the contraction length of the rivet nut after riveting (as specified in Table 2) and the torque of the rivet nut (as specified in Table 3)

test

Check the shrinkage length of the rivet nut after riveting (according to Table 2)

Check the torque of the rivet nut (according to Table 3)

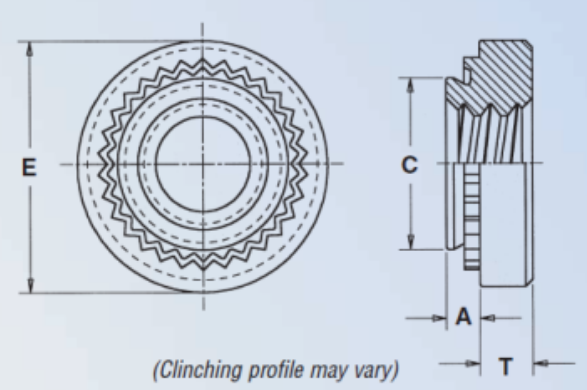

Self-clinching nut

A self-clinching nut is a nut used on thin plates or metal sheets. It is round in shape with a convex tooth and a guide groove on one end. The principle is to press the convex tooth into a preset hole in the metal sheet. Generally, the diameter of the preset hole is slightly smaller than the convex tooth of the self-clinching nut. The pressure causes the teeth of the self-clinching nut to squeeze into the sheet, causing plastic deformation around the hole. The deformed material is pressed into the guide groove, which produces a locking effect.

Material description of self-clinching nuts

The self-clinching nut is divided into S-type, a free-cutting steel self-clinching nut, and CLS-type, a stainless steel self-clinching nut, based on the material. The specifications are usually from M2 to M10.

Check whether the air pressure is within the working pressure range (0.5-0.7MPa). Assemble the pull rod and the pneumatic rivet gun. According to the length of the rivet nut, adjust the insertion length of the pull rod so that the pull rod reaches the last 2~3 threads of the rivet nut. At the same time, adjust the pull rod stroke and check whether the stretching length is appropriate (according to Appendix 2). If the stretching length is not reached, the stroke should be adjusted until the stretching length requirement is met before batch operation.。

Adjusting the Rivet Gun

Check whether the air pressure is within the working pressure range (0.5-0.7MPa). Assemble the pull rod and the pneumatic rivet gun. According to the length of the rivet nut, adjust the insertion length of the pull rod so that the pull rod reaches the last 2~3 threads of the rivet nut. At the same time, adjust the pull rod stroke and check whether the stretching length is appropriate (according to Appendix 2). If the stretching length is not reached, the stroke should be adjusted until the stretching length requirement is met before batch operation.

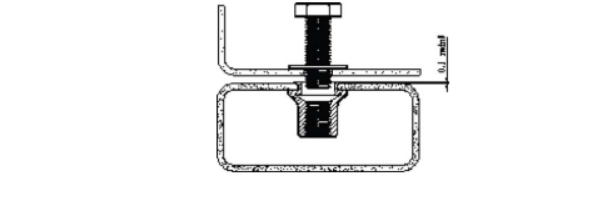

Riveting

Put the rivet nut into the bottom hole. When putting it in, just push it in gently by hand, and never use other tools to force it in. When installing, the rivet nut should protrude from the workpiece by at least 0.1mm. As shown in Figure 2

Figure 2: Schematic diagram of the installation of the rivet nut

After installation, riveting is performed. The riveting gun must be perpendicular to the workpiece surface, and the gun head must be pressed tightly against the workpiece. Detect the shrinkage after riveting (measure after installation, and reinstall if any problems are found), as shown in Figure 3

Function of pull rivet nuts

Pull rivet nuts are mainly used in the fastening field of various metal plates, pipes and other manufacturing industries. It solves the problems of easy melting of welding nuts for metal thin plates and thin pipes, easy deformation of welding, and easy slipping of tapped internal threads. Pull rivet nuts do not require tapping internal threads or welding nuts. The riveting is firm and efficient, and easy to use. It is particularly suitable for situations with limited installation space, such as the inside of closed pipes. It can also be used for slipping on sheet metal. You can re-drill holes and rivet a nut

Function of pressure rivet nuts

Pressure rivet nuts are mainly used for fastening on thin plates or sheet metals. The embossed teeth are squeezed into the plate through pressure, causing plastic deformation and locking. It is suitable for the connection of aluminum alloy profiles and plates, but the connection strength is greatly affected by the strength of the parent material. Pressure rivet nuts require pre-opening of installation holes on the parent material, which is suitable for mass production and can obtain better anti-rotation performance than pull rivet nuts.

Related information

SAF Coolest v1.3.1.2 设置面板 JFSSX-ARNQ-ISAAE-ZWD

无数据提示

Sorry,当前栏目正在更新中,敬请期待!

您可以查看其他栏目或返回 首页