In-Depth Evaluation of Sheet Metal Cost Calculation and Quotation Strategies in China 2025 (RMB)

Data:

2025-06-01 21:09

In-Depth Evaluation of Sheet Metal Cost Calculation and Quotation Strategies in China 2025 (RMB)

Sheet metal quotations comprise costs from these processes:

Material cost, standard parts cost, processing fees (CNC blanking, deburring, bench work, bending, welding, grinding), surface treatment, assembly, and transportation. Only processes specified in the drawing are calculated.

Material Cost (30%-50% of total)

Base Material Cost

Formula: `Material Cost = Unfolded Area × Density × Unit Price × (1 + Wastage Rate)`

Typical Parameters:

304 Stainless Steel: ¥22/kg (2025 market price)

5052 Aluminum Plate: ¥25/kg

SPCC Cold-Rolled Steel: ¥6/kg

Wastage Rate: Laser cutting 5%-8%, Stamping 3%-5%

Scrap Recycling Value

Model: `Net Material Cost = Raw Material Cost - (Scrap Weight × Scrap Unit Price)

304 Stainless Scrap: ¥9/kg (41% of original)

Aluminum Scrap: ¥10/kg (40% of original)

Processing Cost (40%-60% of total)

Cutting Process Cost Comparison

| Process | Unit Price (¥/m) | Application Scenario |

|---|---|---|

| Laser Cutting | 0.5-10 | Thickness ≤20mm, high precision |

| CNC Punching | 0.5-5 | Batch hole processing |

Note: 3000W fiber laser example: Processing Fee = ¥1/m × Cutting Length

Bench Work Cost

Deburring: ¥40/hour

Tapping:

≤M6: ¥0.5/hole (incl. M6)

≥M8: ¥2/hole (incl. M8)

≥M20: ¥3/hole (incl. M20)

Countersinking/Chamfering (90°): ¥0.5/hole

Riveting: ¥0.5/rivet

Bending Cost

Pricing: `Bending Cost = Number of Bends × Unit Price per Bend

Unit Price: Standard bending ¥0.8-1.5/bend, CNC bending ¥1.5-3/bend

Complexity Factor: Z-bend = 2 bends, Hemming = 3 bends

Welding Cost Model

| Welding Type | Unit Price (¥/m) | Efficiency Parameter |

|---|---|---|

| TIG Welding | 8-15 | 0.3m/min (3mm aluminum) |

| Laser Welding | 20-30 | 2m/min (1mm stainless) |

| Resistance Spot | ¥0.5-1/spot | 600 spots/hour |

Core Quotation Methods

Labor-Time Calculation (Small Batch)

Formula: Quotation = (Material Cost + Labor Cost) × (1 + Management Fee Rate) × (1 + Profit Margin)

Labor Rate: Standard equipment ¥80-120/hour, CNC center ¥150-300/hour

Management Fee: 8%-15% (covers site, energy, admin)

Case Study: Stainless Control Box (500×300×200mm)

Material Cost: 1.2m² × 7.93kg/m² × ¥22/kg × 1.06 =¥222

Processing: Laser cut (15m×¥1) + Bend (12×¥2) + Weld (2m×¥12) = ¥63

Quotation: (222+63) × 1.1 × 1.2 = ¥376

Experience Coefficient Method (Mass Production)

Formula: Quotation = Material Cost × K-Factor

K-Factor Range:

Simple Parts: 1.8-2.5 (e.g., flat plates)

Medium Complexity: 3-4.5 (bending/welding)

High Complexity: 5-8 (precision parts)

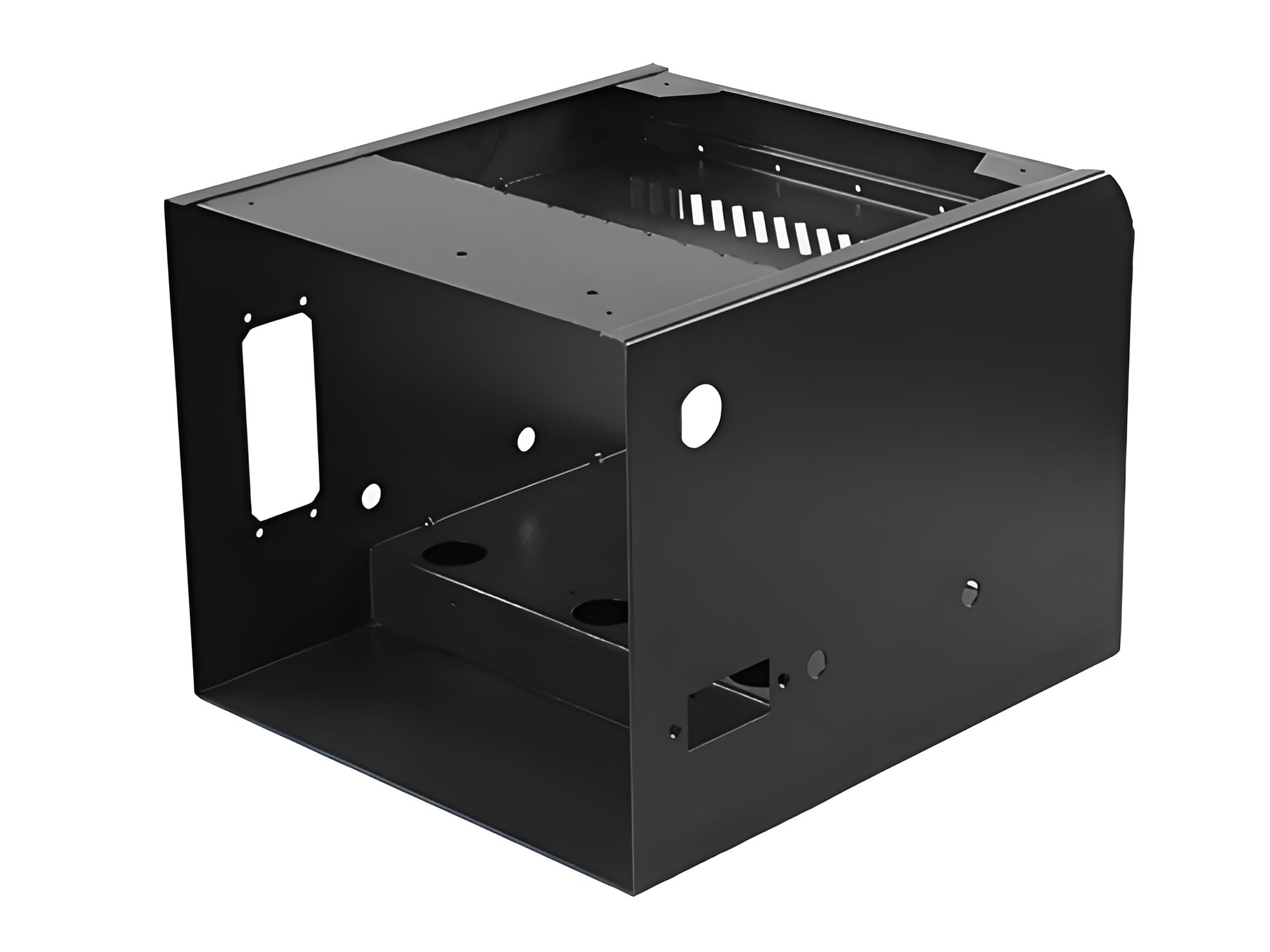

Case Study: Server Chassis (Material Cost ¥200)

10 bends + 5 welds + painting → K=3.5

Quotation: 200 × 3.5 = ¥700

Major Cost Control Points

Process Optimization

Nesting: CAD optimization → Material utilization ↑92%

Case: Optimized nesting increased output from 15 to 18 pieces per sheet

Processing Efficiency

Progressive Dies: Stamping efficiency ↑3× (30s → 10s/piece)

Laser Combo: Cutting/marking/tapping integration ↓ setup time 60%

Surface Treatment Cost

| Process | Unit Price (¥/m²) | Economic Thickness |

| Powder Coating | 20-35 | 60-120μm |

| E-Coating | 50-80 | 15-30μm |

| Anodizing | 40-60 | AA10-AA15 |

Note: Sand texture coating (¥25/m²) costs 50% less than glossy (¥50/m²)

Logistics & Packaging

Standard Packs: 1200×1000×800mm steel containers ↑ loading 40%

Lightweight Design: Topology optimization ↓ weight 15% → ↓ annual transport cost ¥80k

Quality Cost Control

First-Article Inspection: CMM (0.02mm precision) prevents batch scrap

SPC: Critical dimension CPK>1.33 → Defect rate ↓ 3%→0.5%

Tooling Amortization

Progressive Die Life: 500k strokes → Unit cost = Total tooling cost / Output

Case: ¥100k tooling for 50k pieces → Unit cost¥2

Quotation Strategies & Techniques

Differentiated Pricing Models

| Order Type | Strategy | Target Gross Margin |

|---|---|---|

| Small Batch | Cost-Plus (+30%-50%) | >25% |

| Long-Term | Tiered Pricing (volume-linked) | 15%-20% |

| Strategic Client | Target Costing | 8%-12% |

Risk Management

Material Volatility: Price adjustment clauses (±5% trigger)

Currency Risk: Hedge periods ≤90 days

Optimized Quotation Structure

Example:

Material: 304 SS 2mm - 12.5kg × ¥22 = ¥275

Processing:

Laser Cut: 18m × ¥1 = ¥18

Deburring: ¥40

Tapping/Chamfering: M6×5 (¥2.5) + M8×2 (¥4) + Chamfers×6 (¥3) = ¥9.5

CNC Bending: 15 × ¥2 = ¥30

TIG Welding: 3m × ¥12 = ¥36

Surface: Blasting + Coating 2.5m² × ¥30 = ¥75

Management Fee: (275+18+40+9.5+30+36+75) × 10% = ¥48.35

Profit: (483.85 × 20%) = ¥96.77

TOTAL: ¥580.62

Cutting-Edge Cost Control Technologies

Digital Twin Systems

Real-time cost simulation → Material use prediction accuracy 97%

Virtual prototyping ↓ trial costs 80%

Blockchain Supply Chain

Full material traceability (mill → finished product)

Smart Contracts: Auto-execute price adjustments

Sheet metal cost control integrates technical capability and management expertise. By establishing a full-chain system—precise material costing → process optimization → dynamic pricing → digital monitoring—companies can reduce total costs by 15%-25%.

Related information

SAF Coolest v1.3.1.2 设置面板 JFSSX-ARNQ-ISAAE-ZWD

无数据提示

Sorry,当前栏目正在更新中,敬请期待!

您可以查看其他栏目或返回 首页