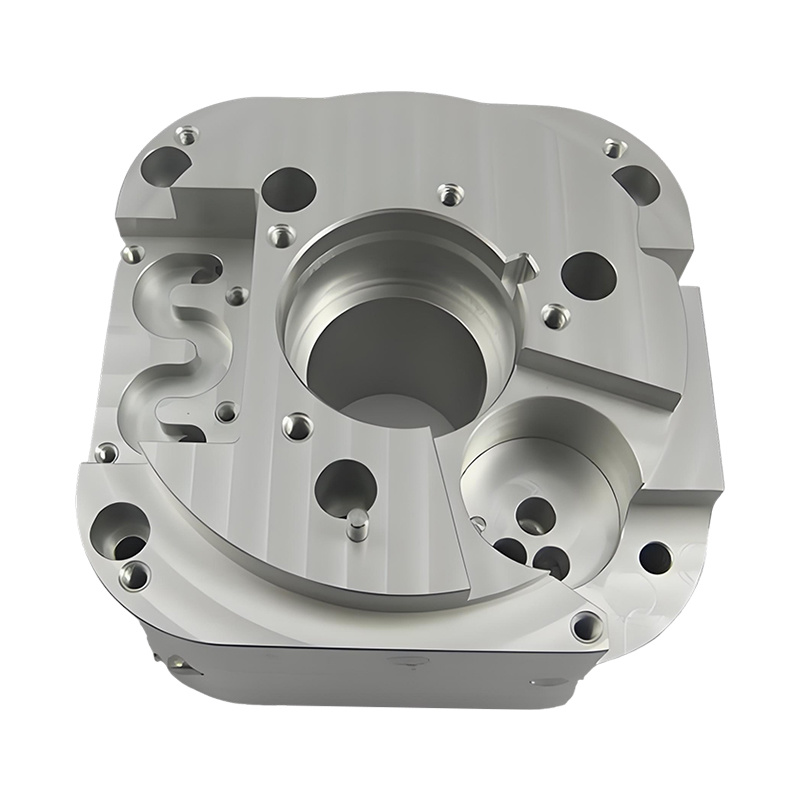

Stainless Steel CNC Workpiece

keyword:

Fixed beam CNC gantry milling machine | gantry guide rail grinding machine | CNC gantry machining center

Category:

CNC Machining

Product Introduction

Avada Precision CNC Turning Capabilities And Features

Avada is capable to provide cost-effective CNC turning lathe services and quality products with high precision and accuracy for vast projects.

Flexible pricing

Fast Quote, Flexible Pricing;

High Dimensional Accuracy,

High Speed and High Reliability.

High Quality

CMM, Pin Gauges, Roughness Machine, Projector and Micrometer, Concentricity measurement; Rapid Prototyping and End-Use Production.

Custom Materials & Finishes

50+ Metals and Plastics, 10+ Surface Finishes; Smooth Surface and Strict Tolerance, Custom Material and Surface Treatment.

High Efficiency

High Productivity and Improved Efficiency;

Low, Medium to High

Volume Production Runs.

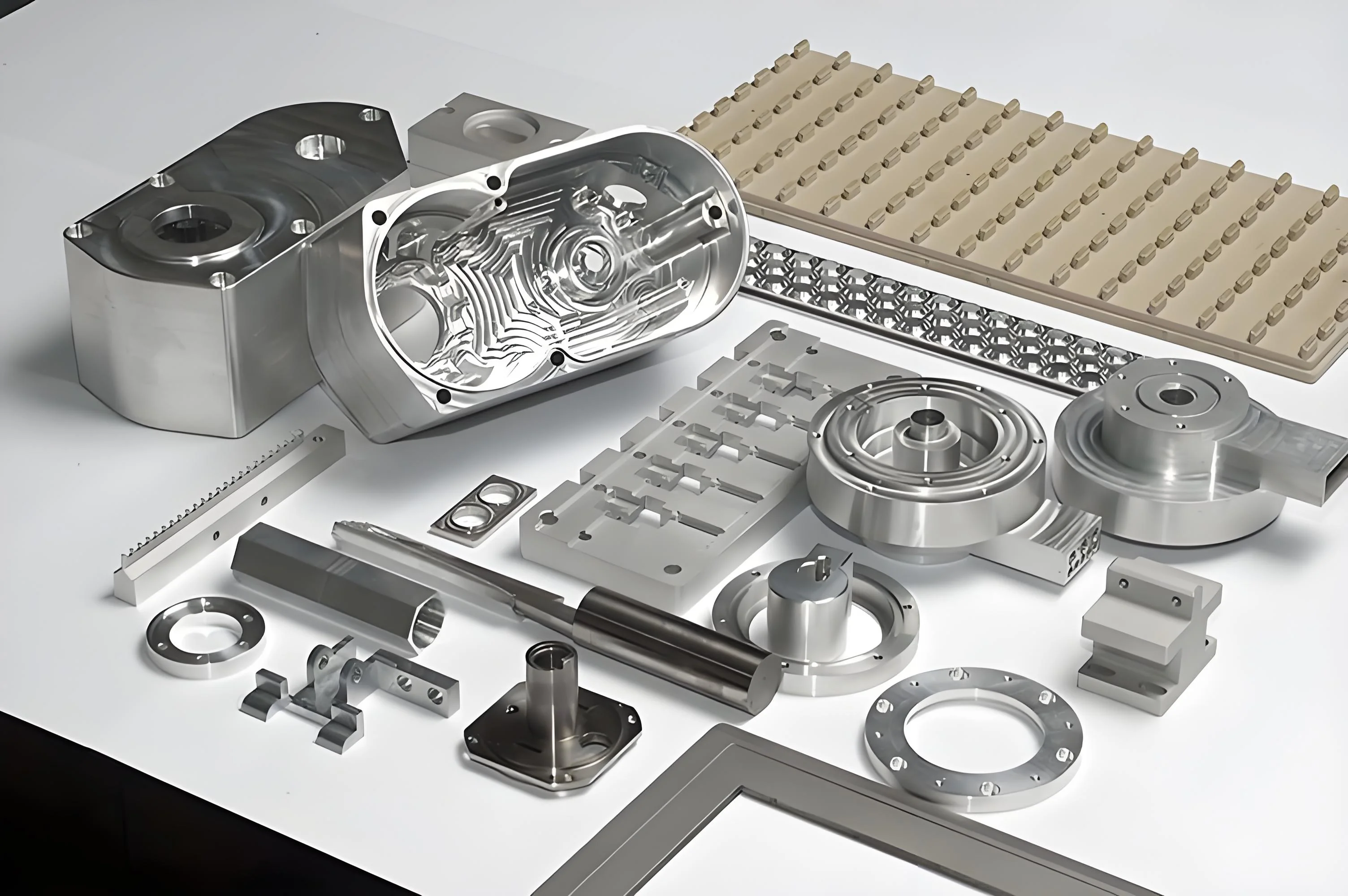

Custom CNC Turning Services And Parts - OEM China CNC Turned Components Manufacturer And Company

Avada is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM CNC lathe services for superior quality low cost CNC lathing/turning parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc.

Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC turned parts. Send your inquiry or drawing fast to get an online CNC quote.

CNC Turning Tolerance At Avada

We have multiple CNC manufacturing capabilities and can meet a wide variety of needs.

1. Size

Threaded Holes

UNC & UNF threads from #2 up to 0.5 in.

Metric threads M1.2 and above.

Radii

turned outside corners will typically include a 0.005 in. chamfer.

Minimum hole size:

- Minimum on-axis and axial: 0.04 in. (1mm)

- Minimum radial: 0.08 in. (0.5mm), 0.04 in (0.5mm) for aluminum and brass

Grooves:

- Minimum OD groove width: 0.047 in. (1.2mm)

- Minimum OD groove width for aluminum and brass:0.019 in (0.5mm)

- Maximum OD groove depth: 0.95 in. (24.1mm)—varies with a groove width

| Linear dimension |

+/- 0.025mm +/- 0.001 inches |

| Hole diameter(not reamed) |

+/- 0.025mm +/- 0.001 inches |

| Shaft diameter |

+/- 0.025mm +/- 0.001 inches |

| Part Dimension limit |

950*550*480mm 37.0 * 21.5 * 18.5 inches |

2. CNC Machining Standards

| CNC Machining Standards (DIN ISO 2768-1(1991-06) | ||||||||||||||

| Tolerance class | tolerance(mm) | |||||||||||||

| Metal (ISO 2768-F) | Plastic (ISO 2768-F) | |||||||||||||

| 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

2.1 General Tolerances For Shape And Position

| General tolerances for shape and position (DIN ISO 2768-2(1991-04) | ||||||||||||||

| Tolerance class | tolerance(mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.02 | ±0.05 | ±0.1 | ±0.2 | ±0.3 | ±0.4 | ±0.2 | ±0.3 | ±0.4 | ±0.5 | ±0.5 | |||

CNC Turning Materials At Avada - Materials Used For CNC Turning Services

CNC turning service can be applied to a wide variety of materials, including metal, plastic, and wood. Different lathes are needed for turning metal and wood. According to the types of machined part materials, certain maintenance and safety precautions may be required for the lathe. Here are some common materials for CNC turning manufacturers below. If the material you required is not listed in the table, please contact us.

| Material | Available Types & Grades |

| Aluminum |

Aluminum 2024 Aluminum 5052 Aluminum 5083 Aluminum 6063 Aluminum 6061 Aluminum 6082 Aluminum 7050 Aluminum 7075 |

| Brass/Bronze |

Brass C360 Brass 260 C932 M07 Bearing Bronze |

| Copper |

Copper C110 Copper 101 |

| Steel |

Alloy Steel 4130 Alloy Steel 4140 Mild Steel 1018 Mild Steel A36 |

| Stainless Steel |

Stainless Steel 17-4 Stainless Steel 18-8 Stainless Steel 303 Stainless Steel 304/304L Stainless Steel 316/316L Stainless Steel 416 Stainless Steel 420 |

| Titanium |

Titanium Grade 2 Titanium Grade 5 |

| Plastics |

ABS Nylon POM PEEK PMMA PTFE Polystyrene Polyethylene Polycarbonate |

CNC Turning Surface Finishes At Avada - Surface Finishing Process For Turned Parts

Here is a wide selection of metal surface finishing services at your choice for the machined CNC turning parts to improve the part appearance, surface smoothness, corrosion resistance, and other characteristics.

| As machined | Description |

| As machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat) |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Forming a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at a high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit resulting in a unidirectional satin finish. |

| Chromate Conversion Coating | Increase the corrosion resistance while maintaining conductive properties. |

Related Products

Cooperation Intent Form

SAF Coolest v1.3.1.2 设置面板 JFSSX-ARNQ-ISAAE-ZWD

无数据提示

Sorry,当前栏目正在更新中,敬请期待!

您可以查看其他栏目或返回 首页